Technologies in Cables

pressing instead of a screw clamp

Solid Grip Technology

When connecting loudspeakers and audio amplifier with a bare wire causes the exposed copper to oxidize quickly which increases the cable resistance and has a detrimental effect on the fidelity of the sound we hear. That is why high-class cables rely on f.e. banana plugs.

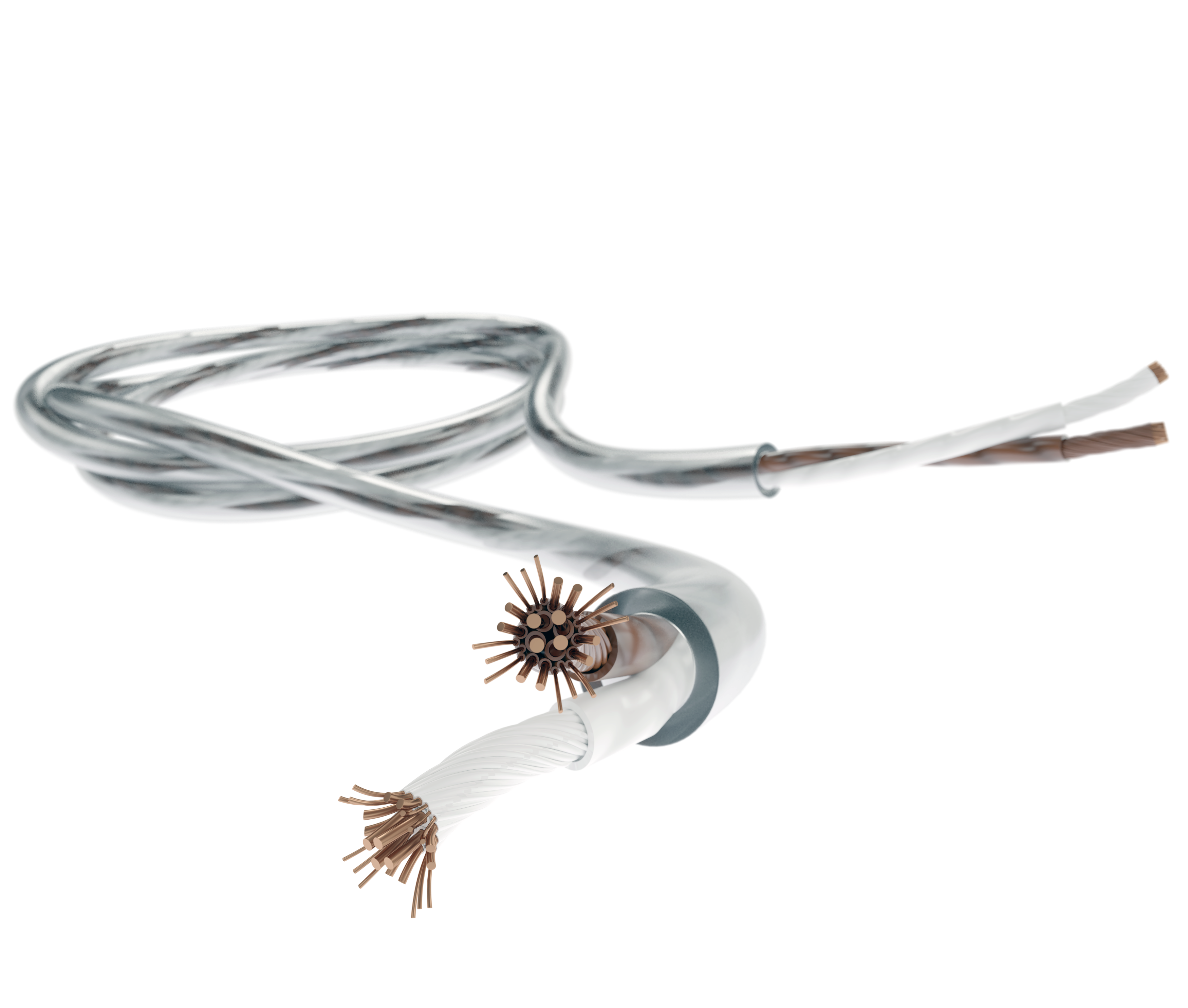

A special technology for tight connection of the plugs to the speaker cable without the use of soldering - Solid Grip Technology. Contrary to the standard connection technique, i.e. with the use of screw terminals, Solid Grip Technology involves crimping a properly prepared plug on the loudspeaker cable with a press. This allows all conductors to be tightly pressed together with the plug in a way that eliminates gaps between them and maximizes the contact area. The monolith obtained this way forms a smooth, uninterrupted signal path, which significantly reduces the connection resistance.

The cable and plug pressed into one unit using Solid Grip Technology offer a much higher conductivity than a terminal made with screws or soldered joints. Using this solution results in a reliable, durable connection that is resistant to oxidation and offers excellent electrical conductivity with reduced resistance.

Multi-Gauge Core

Multi-Gauge Core Technology is the special cable construction which employs conductors of different thicknesses for low, medium and high tones. Two braids of intertwined conductors eliminate self-interference. The current induced in one conductor has the opposite direction to the neighboring one, so that interference cancels each other out. The thickness of individual conductors has been adapted to the specific cable types.

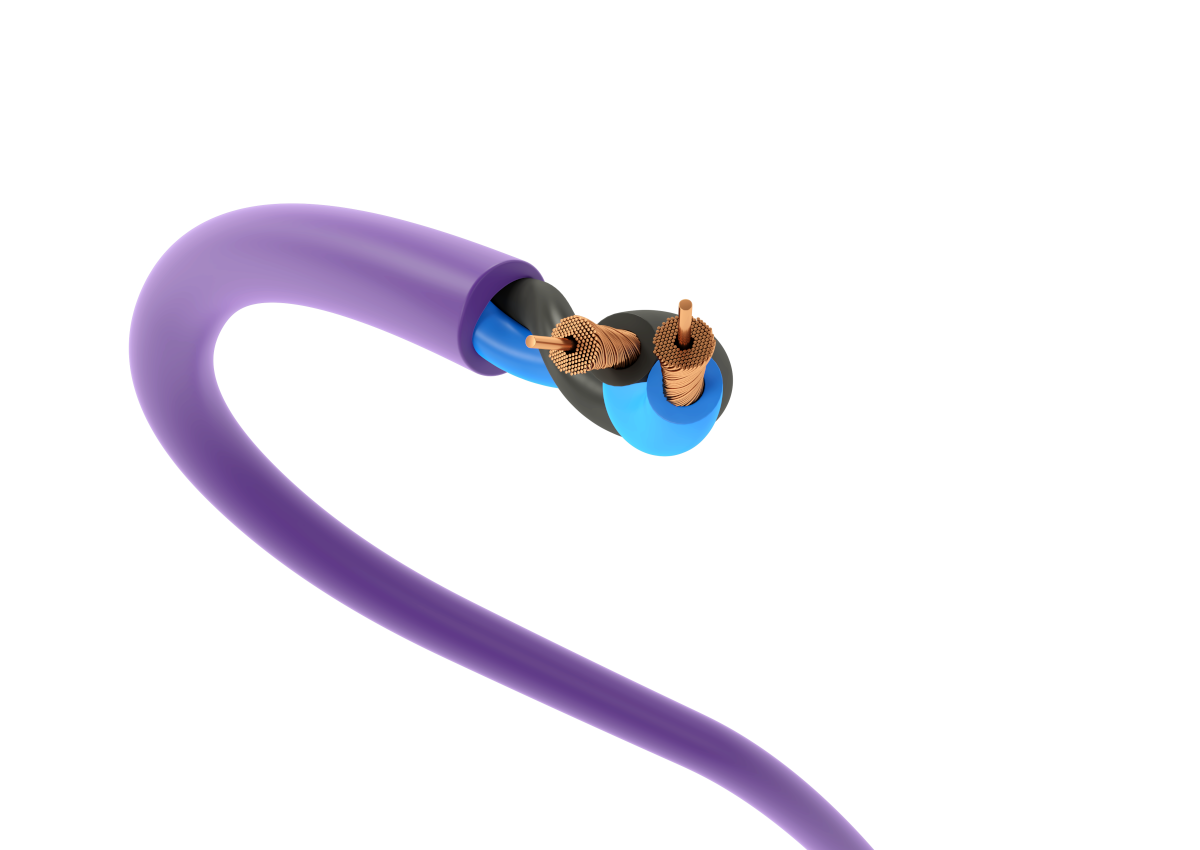

Spiral Litz Technology

In Melodika cables, the individual conductor braids are placed in separate insulation and twisted together. As a result, the total current located on the power amplifier output flows in each core.

The advantage of this solution over standard stranded cables is the even distribution of the signal across the entire cross-section of the cable. It also prevents the loss of the so-called subtle information, which occurs when electrons jump from strand to strand.

The electrons follow their own path, without interruptions, and the skin effect is virtually eliminated. In addition, the fact that the conductor is separately insulated and twisted protects the copper against oxidation and increases the durability of the wire.

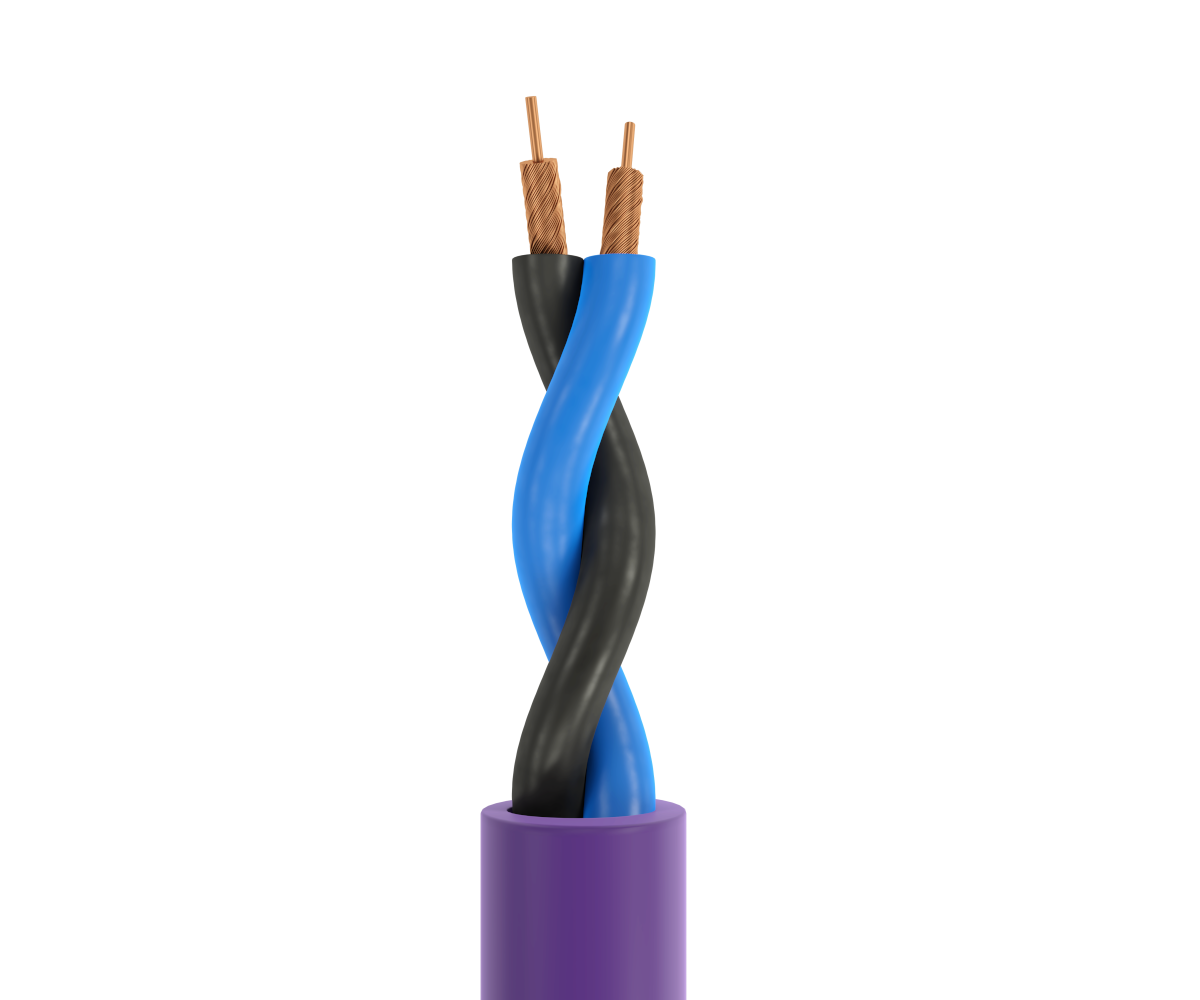

Twisting of the cable cores

Two braids of intertwined conductors eliminate self-interference. The use of a helically twisted braid (pigtail) means that the cable's sensitivity to interference is low. The current induced in one conductor has the opposite direction to that induced in the neighbouring conductor - so that interference cancels each other out.

This solution was promoted by Alexander Graham Bell (scientist, inventor of the telephone and dozens of other telecommunications inventions), who in 1881 proved that this method of arranging the conductors reduces the impact of EMI interference and mutual interference called crosstalk.

LDPE Technology

LDPE (foamed low-density polyethylene )

The low-capacitance dielectric insulation made of LDPE (foamed low-density polyethylene) protects against mechanical damage. The outer insulation of increased resistance means that the cables can be laid under plaster or concrete without fear of damaging the cable.

BassCore

Our research has shown that a cable with a bass core transmits low frequencies better. Therefore, while constructing the loudspeaker cables of the various series, BassCore Technology was used - a bundle of fine conductors, usually 0.15 mm thick, surrounds a thick core, the so-called "BassCore".

Depending on the model, the structure of the conductor in the cables varies in thickness. The balanced construction makes the cable sound excellent across the full bandwidth spectrum, with a slightly warmed and deeply diving low range.

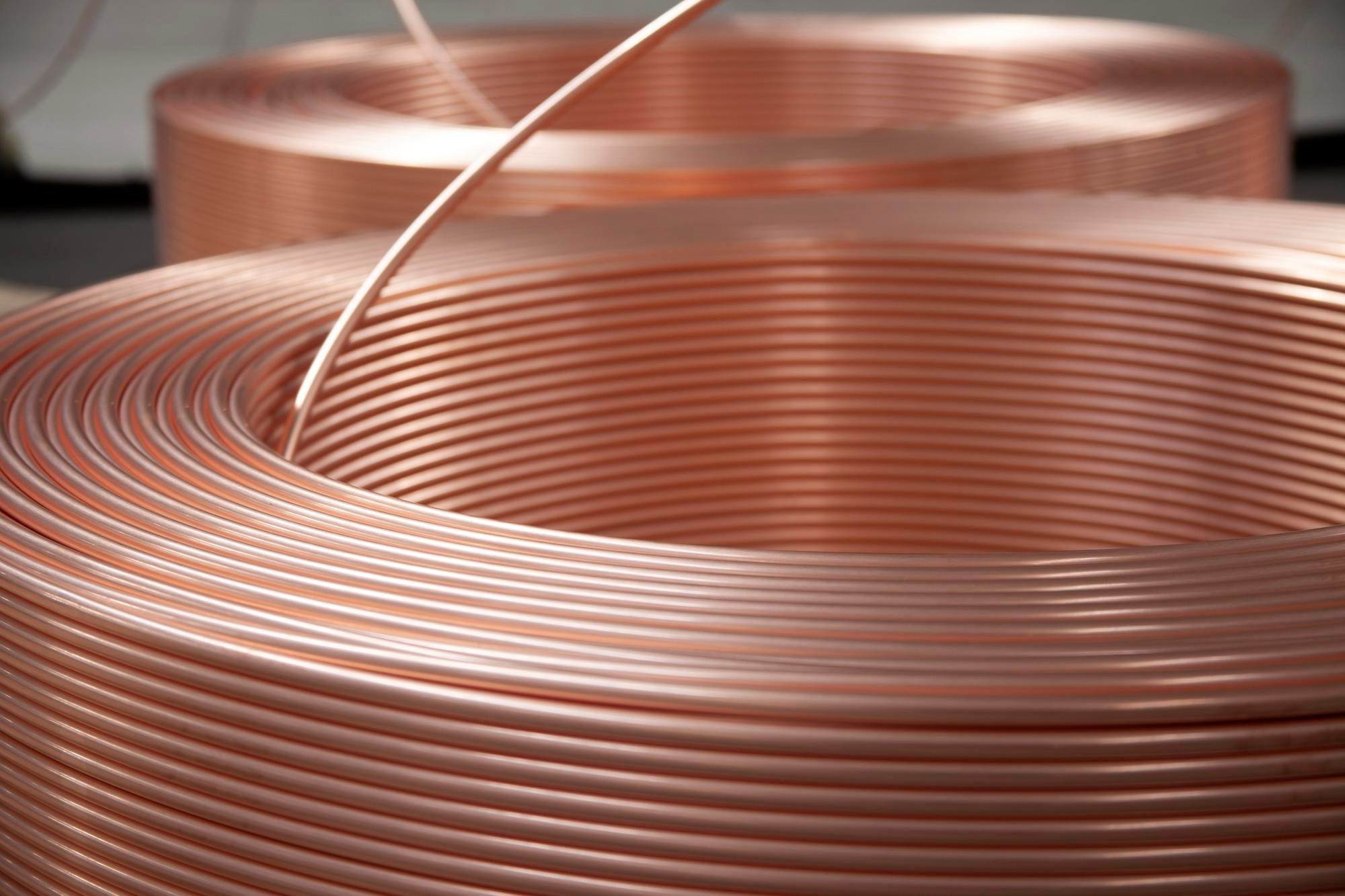

Polish copper

Copper is one of the best conducting materials under normal atmospheric conditions. It has low electrical resistance, which means it can effectively transmit electrical signals such as sound. The Polish copper which we use to create Melodika cables, is a guarantee of high product quality and high efficiency of audio signal transmission.

The use of Polish copper is also a matter of ecology - using local resources helps to minimize the carbon footprint. In addition, KGHM Polska Miedź S.A., our supplier of this raw material, complies with international environmental standards, implements eco-efficient and low-emission technologies and ensures standards aimed at protecting the health of residents and natural resources in the region.

PTFE insulation

The insulation of the plugs is made of a special material (polytetrafluoroethylene) resistant to temperatures up to 320°C, which is also characterized by exceptional chemical resistance (it does not react even in concentrated acid). The plugs constructed in this way guarantee excellent insulation and exceptional resistance. The predicted connection cycle for Melodika plugs is over 2000 cycles. When the cable is soldered, the insulation is not overheated and thus the plug construction is not affected in even the slightest way, so the transmitted signal is not disturbed in any way. Furthermore, the PTFE-type insulation does not store electrostatic charge - making it an excellent insulator.

Shielding

Shielding braid made of copper with a high percentage of coverage ensures very high resistance to any interference. To further increase the shielding effectiveness, a layer of metallised Mylar film is used on some models to ensure 100% coverage.

Due to its higher thickness, the braided copper conductors absorb more EMI (ElectroMagnetic Interference), especially at lower frequencies. The second layer of shielding is formed by Mylar foil, which, being thinner, absorbs less interference but offers better protection over a wider frequency spectrum.